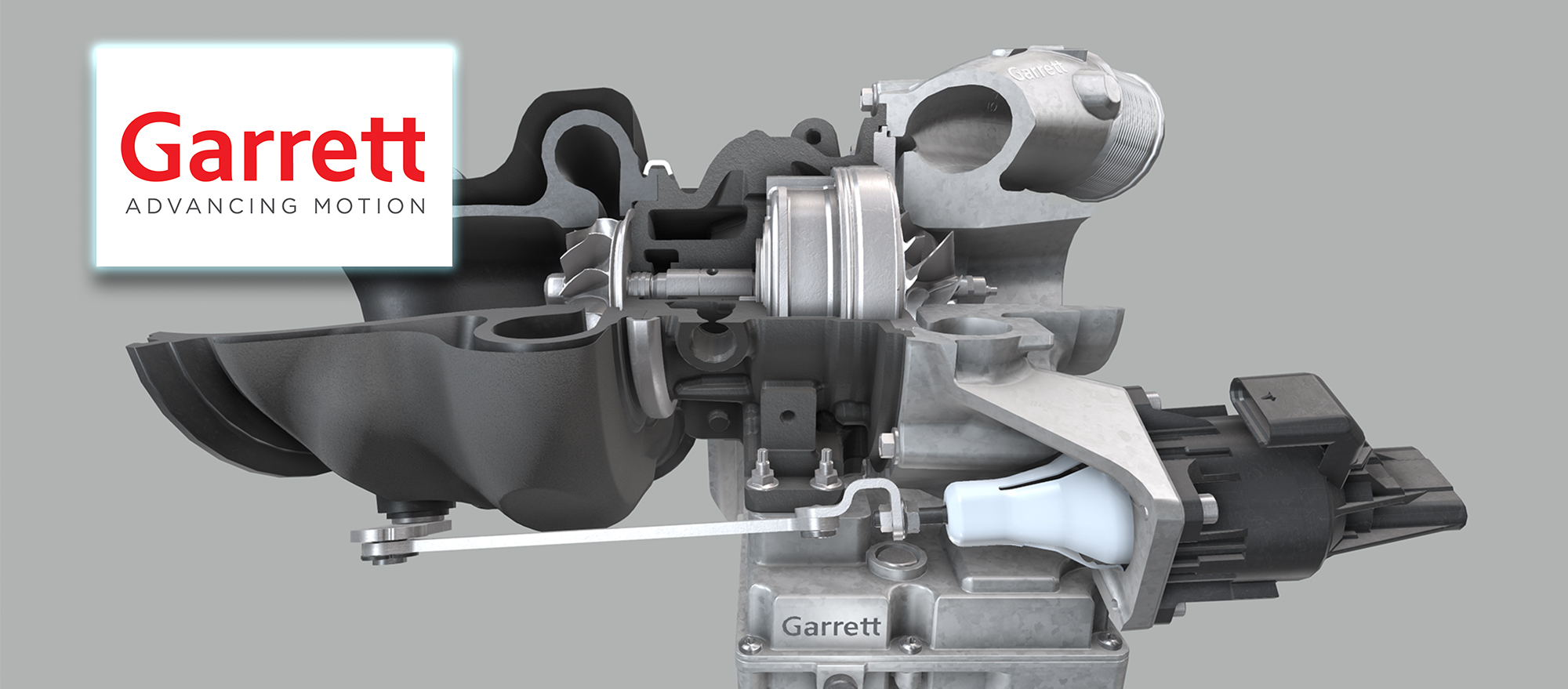

E-turbo for hybrid powertrains

Pushing the boundaries of turbocharged compact engines

Over the past decade, automotive manufacturers have adopted down-sized boosted engines to comply with fuel economy and emissions regulations. Stricter regulations combined with Real Driving Emission boundary conditions have however recently reversed this trend replacing it with engine right-sizing. To meet future fuel economy and emissions regulations, engineers would ideally develop smaller engines with boost systems offering the efficiency of a large turbo and the response of a small turbo.

Garrett has moved to the next level in turbocharging with its E-Turbo for hybrid powertrains, which enables manufacturers to push the boundaries of engine downsizing.

The compact machine is as efficient as a large turbo, obliterating turbo lag thanks to a high-speed electric motor positioned directly on the turbo shaft between the compressor and the turbine.

Garrett had to develop a high-speed E-Motor, high-frequency inverter combined with high-current power electronics in the super-tight space available between the compressor and the turbine while making it durable in the worst possible conditions for electric and electronic components (high temperatures, severe vibrations, oil, water).

In addition to the significant packaging benefits, the Garrett E-Turbo can also recover energy, unlike an electric supercharger. It is a net electric energy provider, part of a complete vehicle energy management system.

The first application to go into production in 2021 with Mercedes-AMG will be a high performance four-cylinder gasoline engine. In a hybrid vehicle, the E-Turbo combines the fuel economy and emissions of a four-cylinder with the performance and fun-to-drive aspects of a much bigger engine. Garrett is also engaged in multiple pre-development programmes for gasoline, diesel and commercial vehicle applications.

Back

Back